Inline Check and Relief/Check Valves

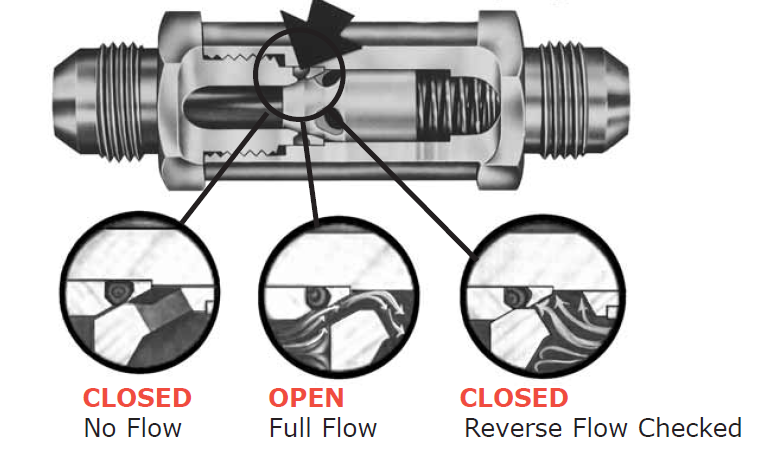

These spring-operated poppet valves, with optional relief settings, allow free flow in only one direction and prevent backflow – sometimes referred to as “backflow preventor”, “flow stop”, or “non-return” valve. They also are used for relief and by-pass functions; however, they should not be used as safety relief valves. Kepner's Flexible Seal Seat™ combines metal-to-metal contact with a resilient seal seat ensuring dependable bubble-tight shutoff of liquid or gas, and long service life. Standard and specialty valve designs handle a wide variety of applications.

Features and Benefits:

•Flexible Seal Seat™ for zero leak (bubble-tight) seal at low and high pressures

•O-Ring seal positively secured

•Non-pressurized threads

•Poppet stop inside valve body prevents spring from bottoming out

•Generous flow passages allow full flow with minimal pressure drop

Standard Valve Specifications:

• See Applications for selection/ limitation notes about O-Ring and Valve materials

• End Connections: Pipe or Tube (NPT, JIC; 12 combinations)

• Port Sizes: 1/8 inch to 3 inch (3.2 mm to 76 mm)

• Body Materials: Aluminum, Brass, Steel, 303 or 316 Stainless Steel

• O-Ring Seals: Buna-N, Neoprene, Viton®, EP, others available

• Temperature: -300°F to 450°F (-184°C to 232°C), O-Ring dependent

• Check Crack Pressure: 1 to 2 PSI (.07 bar to .14 bar)

• Relief/Check Crack Pressures: 5 PSI (.35 bar), 10 PSI (0.7 bar), 25 PSI (1.7 bar), 50 PSI (3.5 bar) and 65 PSI (4.5 bar), others available

• Operating Pressure: to 3000 PSI (207 bar)

• Flow: to 500 GPM (1893 LPM).